Tenant Improvement Project – Minneapolis, MN

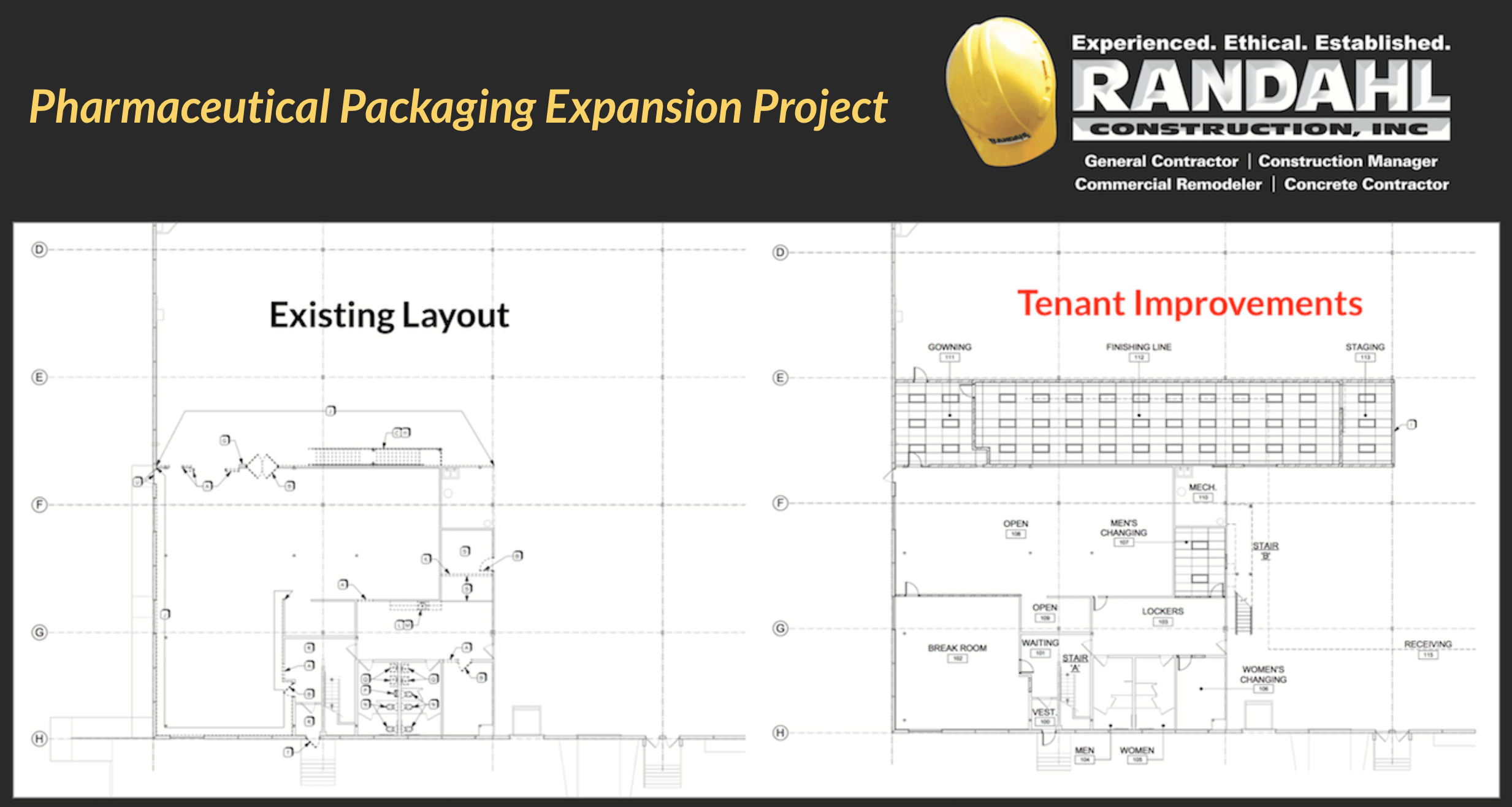

One of our long time customers in the pharmaceutical industry recently approached us to help them with a tenant improvement project at one of their Minneapolis, MN locations. The purpose of this project was to renovate a portion of their warehouse to accommodate a new packaging suite and support areas (offices, change rooms, break room etc). The packaging suite was built to consume an existing open space storage area that had unfinished flooring. The rest of the project would include remodeling existing office areas within the current space.

Project Details:

Project Details:

Stair Relocation:

One of the first stages of the project was to relocate existing stairs from one wall to another. This allowed for the packaging area to be strategically placed with out having stairs from the second floor coming into the room. To some, a simple stair move may sound like an easy process but these were no ordinary stairs. These stairs were concrete filled and needed heavy machinery and extreme care when relocating. Once the stairs were moved we created the new opening from the second floor and closed off the existing doorway.

Building Addition – New Packaging Suite

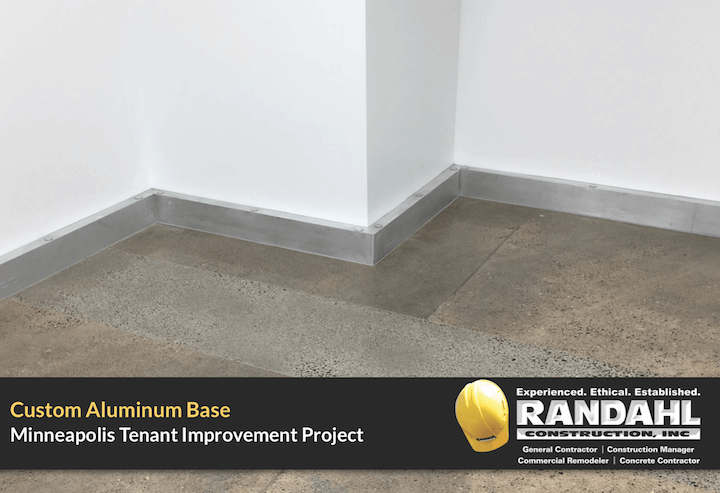

The packaging suite was the focal point of this Tenant Improvement Project – Minneapolis, MN and we wanted to really make this portion of the project amazing. To the clients request we added as many lights as the room could handle and the walls and ceilings were painted bright white offering an amazing glow to the room. Although the ceilings were 26’ high we hung acoustical ceilings enclosing the packaging suite. We fabricated custom aluminum base to protect the walls and really give the space a clean fresh look. The client ordered a custom door for product entry and exit and we installed one standard window in the room. With the high security needed in the pharmaceutical industry we went out of our way to reinforce the exterior walls of the packaging suite ensuring our client that their building was secure. We finished the room off with a sharp polished concrete look really making the floor pop. We convinced our client to go with the polished concrete floor over standard flooring do to the many benefits of polished concrete flooring.

Break Room Addition

The existing space had a large open area that that we installed new flooring, additional lighting, new cabinets that really brighten the space up for a fresh new break room for the employees. The dark countertops and light cabinets were a really good combination and the clients were very satisfied. We did not replace the acoustical ceilings in the portion of the building although we did move some tiles around freshening up the ceiling. The flooring was installed after we did some concrete repair and concrete leveling making the concrete floor level prior to installing the new VCT flooring. The fresh flooring offers a clean and professional feel to the room and really finished off the room well.

The existing space had a large open area that that we installed new flooring, additional lighting, new cabinets that really brighten the space up for a fresh new break room for the employees. The dark countertops and light cabinets were a really good combination and the clients were very satisfied. We did not replace the acoustical ceilings in the portion of the building although we did move some tiles around freshening up the ceiling. The flooring was installed after we did some concrete repair and concrete leveling making the concrete floor level prior to installing the new VCT flooring. The fresh flooring offers a clean and professional feel to the room and really finished off the room well.

Bathroom Remodel

The bathrooms were not the focus of the remodel project although we did install new vanities and sinks in the bathrooms really cleaning them up and giving them a fresh feel. The restrooms also were equipped with some new partitions.

Office Space Renovations

With office being located above the break room and gowning rooms we were able to do some minor upgrades to improve the space. We removed some walls increasing the size of certain offices and also created a new exit door into the warehouse. With new carpet, paint, and minor drywall repairs the second level  offices were updated to create a fresh new feel to the space.

offices were updated to create a fresh new feel to the space.

Building Fire Safety

We worked directly with the sprinkler contractor throughout the project ensuring that the building was properly sprinkled and the sprinkler system was effective.

Sterile Gowning Rooms

With the pharmaceutical’s demand for sterilization we also remodeled a downing area for the employees prior to entering the packaging suite. This area was well lit and included the clean and sterile feel of the packaging room with polished concrete.

Construction Project Summary

In summary, with the help of Randahl Construction our client was able to maximize the space of their facility and create a state of the art packaging suite for their business. We could write all day and create a beautiful project summary but it means nothing if our customer is not satisfied. Here is some feedback directly from them:

“Randahl Construction met our needs with a well-executed and on time delivery of our new facility. The end result looks better than we expected!”

~ Facilities Engineer