Division: Minnesota Masonry Contractor (Concrete Division)

Customer: Beaver Machine & Tool

Location: Crystal, MN

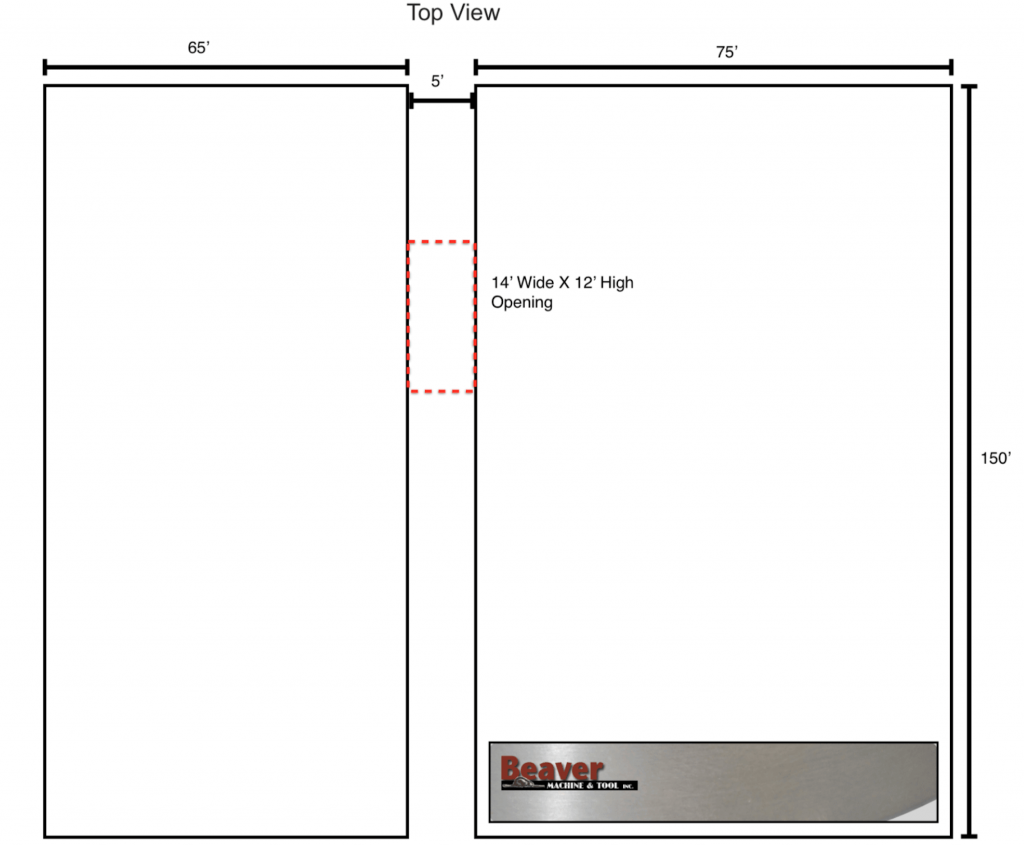

Project Scope: Beaver Machine & Tool, a manufacturer of precision machined parts and assemblies, recently acquired a building right next to their existing property located at 5273 Hanson Court in Crystal, MN. Prior to the purchase, President Jay Groth reached out to Randahl Construction, a Minnesota Masonry Contractor, to see if we could help him design and price out the costs of construction for a tunnel that would connect the two buildings. After meeting Jay on site and reviewing the project, our team began putting together a design and proposal for the project. We met with the local Crystal Building Inspector insuring that our design was within code and presented Jay with the design and costs for the project. The project was approved, Jay closed the deal on the real estate transaction, and we broke ground.

Construction Project Details:

Prep: The first step in the project was to build a shelter that would protect the area from the Minnesota winter elements.

Security & Protection: Build dust barriers / temporary walls inside the occupied building and also on the exterior for security.

Shoring: Our shoring contractor provided an engineered shoring system for both buildings. Our masonry crew saw cut all of the necessary holes in the building in order for the shoring to be installed. The shoring allowed our team to demo the existing walls where the tunnel is going with out having the block building cave in. (pictures below)

Excavation: Our team excavated in between the two buildings, below the frost line in preparation for the tunnel floor footings. After removing the necessary dirt they formed and poured the the floor footings battling the Minnesota weather. They heated the area inside our shelter ensuring that the enclosure had the proper temperature when pouring the footings.

Demolition: After the footings were poured we started the demolition process. One wall at a time, our team used jack hammers, mauls and other tools to dismantle the block walls.

Concrete Block: There was a lot of concrete block work in this project. Jamb blocks, below grade work and all walls needed to be built with concrete blocks.

Concrete: Along with the footings, concrete was used for the tunnel floor that was poured with 8″ thick concrete. The concrete floor in between the two buildings was connected with the pin and dowel method.

Structural Steel: In the design process our structural engineer designed the proper amount of structural steel needed for the tunnel. This included two headers, deck plates, etc.

Roof System: Our team finished the project by adding a slanted roof to the tunnel.

Overall the project was a great success, Jay and his team expanded operations into the new building using the tunnel daily.

Minnesota Masonry Contractor – Project Photos