Cold Weather Masonry: Why the Temperature Matters

The winter time in Minnesota is not the most ideal time to be laying block or doing exterior masonry work as a Concrete Block Masonry Contractor, although with the proper tools, team and preparation it can be done.

In concrete block construction, the mortar is the workable paste used to bind the concrete blocks together and fill the gaps. Mortar is a made by mixing cement and sand together with water. When the water is added to the mix it activates the cement in which the blocks adhere together. Once dried the mortar creates and extremely strong hold for the blocks. Using water in this process, forces Masonry work in the cold Minnesota weather to be difficult. The cold weather causes a slower hydration in the mortar (cement & sand) so when the water is added to the mortar, the cement is activated so when laying brick the water can freeze producing a destructive change in volume causing the mortar expansion. If the mortar contains more than 6 percent water, the expansion due to freezing will be great enough to crack the mortar. Cracks in the mortar weaken the structural integrity of the wall.

This problem can be solved by maintaining a heated work zone. The heated enclosure will keep the mortar at the recommended temperature until it throughly dries.

Concrete Block Masonry Contractor = Adding a Door in a Block Wall

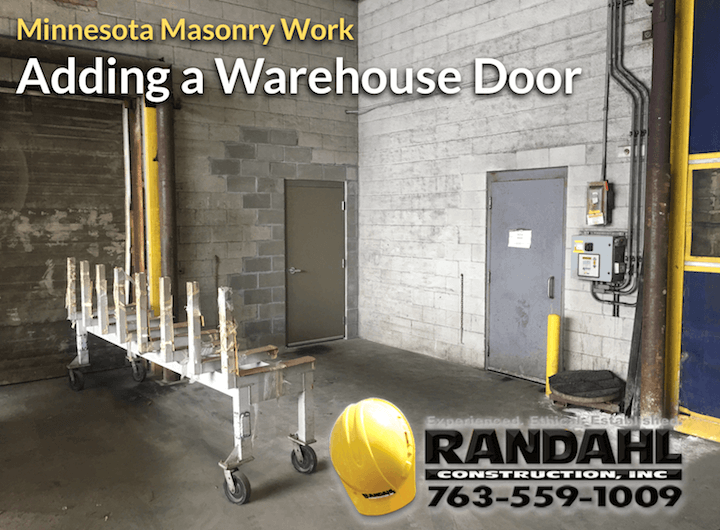

We recently completed a project for a client in Plymouth, MN that was looking to add an additional door in their warehouse. This interior/exterior warehouse door would connect an area of their production facility to the truck dock, where they load and unload materials. Prior to the door being installed, the building and plant design forced employees to walk through a high traffic area and also an additional 100′ to reach the dock area. The only problem?? It was the middle of winter and as explained above this caused some issues.

1. Measuring & Planning for the Door – After our client chose the general area for the door, our team used laser levels to mark and measure out the new door area on both sides of the existing block wall.

2. Dust & Heat Enclosure – Because one side of this door was exterior, our team built dust and heat enclosures on both sides of the wall. This helped contain the dust and also maintain a steady temperature when they layed the block. 40 degrees is the magic number when laying block, so heaters were necessary.

3. Concrete Saw – Our concrete specialists used a diamond blade concrete saw and cut the opening for the new door and disposed of the old blocks. Our team also noticed some block that was damaged very close to the area of the door, so with the approval of the client they took out a few extra blocks at no added charge.

4. Setting the Door Frame – Making sure the door was plumb level and square is one of the most important steps in this project. Continually checking this is key to a successful project.

5. Laying Block – With the door opening cut, we thoroughly cleaned up the area, brought in the new material and prepped the area for installation. The two man crew then mixed their mortar and began installing the door brick by brick. Craftsmanship and consistency was a must in this situation because the door will be installed in a high traffic area and needs to be perfect.

With an area that was already heated and enclosed, it made it easy for our team to keep the area blocked off until the mortar was properly set. Once the mortar was hardened our team then removed the enclosures and gave the area a final clean up.

Contact Us – Your Minnesota Concrete Block Masonry Contractor

If you are located near Minneapolis, MN and have a masonry project that you would like us to look at, please give us a call at 763-559-1009 or simply fill out Masonry Project Request Here.